Recently, the ASME joint inspection work of Henan Dinak air separation has been successfully completed, Dinak Air Separation Group Mr.Gao and members of the forensics leading group attended the joint inspection meeting, and successfully passed the inspection and affirmation of the American ASME joint inspection team. This is a full affirmation of Dinak Air Separation's quality control system and manufacturing capabilities.

In order to meet the certificate obtain work, all employees of the company attach great importance to it. In accordance with the certificate obtain procedures, the ASME joint inspection team conducted inspections of the ASME material area, welding material warehouse, demonstration product site and non-destructive testing room. The JIU made recommendations on the problems existing in the manufacture of the demonstration products, and checked the quality control manuals, procedural documents and records generated during the manufacture of the demonstration products.

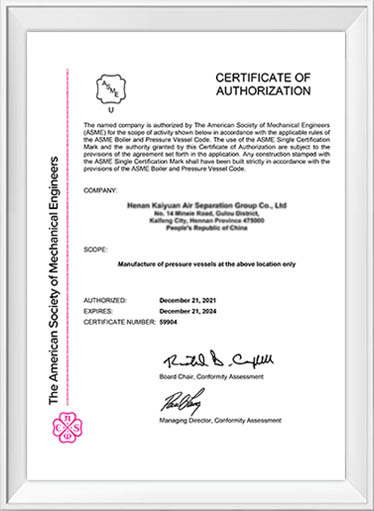

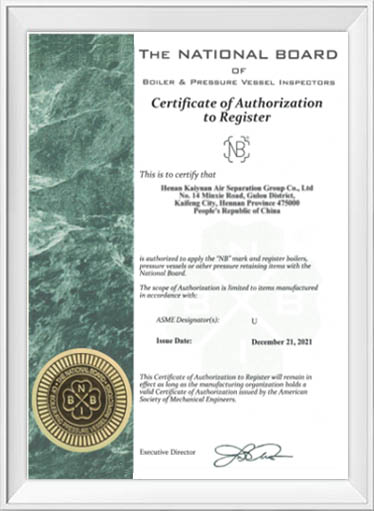

After two days of strict review, the head of the joint inspection team, Mr. Zhang, announced at the final meeting: Henan Dinak Air Separation Group Co., Ltd. ASME quality control system documents and quality control system operation met the requirements of ASME specification, and the certification was successfully passed.

At present, the global epidemic situation is serious, we are going against the current, and we need to be hard on ourselves. The acquisition of the ASME certificate and U stamp not only fully affirms the company's quality control system and manufacturing capabilities, but also encourages Dinak Air Separation to continue to strengthen technological innovation, enhance core competitiveness, and continue to play an exemplary role in the field of air separation manufacturing.

Strive for excellence, create an international brand with quality innovation

Henan Dinak Air Separation Group was established in 2000, and has been rooted in the field of air separation manufacturing for 22 years. A2 class pressure vessel design license and manufacturing license, GC1, GC2, GC3 class pressure pipeline design license, GC2, GC3 class pressure pipeline installation license, ISO9001, GB/T28001, GB/T24001 system certification, American UL certification, etc. At the same time, it has the technical capabilities of design, manufacture and installation of 80,000-level and 100,000-level air separation plants. It has been approved as "Henan Province Energy-Saving Air Separation Plant Engineering Technology Research Center", "High-tech Enterprise" and other certifications, and participated in the compilation of a number of industry standards, contributing wisdom and strength to the standardized and orderly development of the industry.

In the future, Dinak Air Separation will continue to increase investment in R&D and quality control, continuously update technology, upgrade equipment, and process innovation in the field of air separation manufacturing, and strive to achieve overall improvement from R&D design, equipment production to quality control, and consolidate the core At the same time of technological advantages, it realizes the double leap of innovation and quality!

内页小-430x246.jpg)

-430x246.jpg)

-1-430x246.jpg)